News & Insights

Precision Gage Manufacturing: How Veit Tool Ensures Accuracy and Quality in Every Gauge We Build

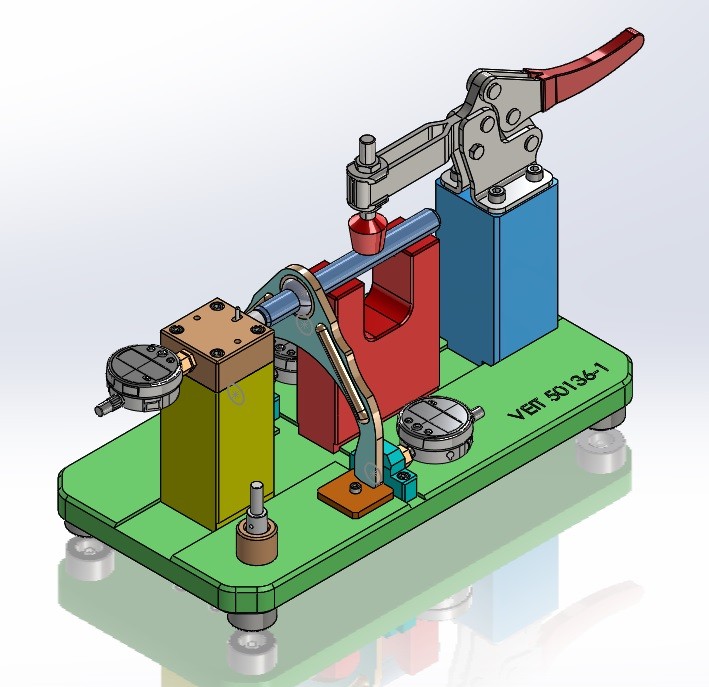

At Veit Tool, precision is our baseline. Every gage we build is engineered to perform under the strictest tolerances, because we understand that the accuracy of your parts depends entirely on the accuracy of your measurement tools. From aerospace to automotive, customers rely on our expertise in precision gage manufacturing and our deep commitment to quality control tooling to deliver custom tools they can trust, job after job.

Precision Gage Manufacturing Begins With Engineering Expertise

At the heart of Veit Tool’s success in precision gage manufacturing is our engineering team. Every gage begins with an in-depth understanding of the application. Whether we are building a standard gage or a fully custom fixture, our engineers analyze dimensional tolerances, part geometry, and inspection requirements before a single chip is cut.

Using SolidWorks and Mastercam, we model each tool with exacting detail. Our ability to simulate the machining process allows us to optimize setups, reduce tool wear, and eliminate errors before production begins. This proactive approach is critical for ensuring consistency and reliability in every gage we build.

Advanced CNC Technology Supports Our Precision Gage Manufacturing

Precision does not happen by accident. It requires the right equipment, and a team that understands how to bring it all together. Veit Tool’s production floor is equipped with advanced CNC lathes, mills, and grinding equipment, all maintained to tight standards.

We work primarily with tool steel and other hard materials common in quality control tooling. Our machines are capable of holding tolerances up to ±0.00005 inches. This level of repeatability is crucial for manufacturing master gages, fixed limit gages, and specialty tools that demand micronic precision.

Quality Control Tooling Starts With Raw Material Verification

Before production begins, every material that enters our shop is verified for composition, hardness, and conformity to spec. This is a critical first step in quality control tooling, because even the best machining processes cannot overcome subpar material quality.

We work with trusted material suppliers and document every step of the chain of custody. From certs to inspections, nothing is left to chance.

In-Process Inspection Drives Repeatable Results

A key reason Veit Tool is a leader in precision gage manufacturing is our commitment to in-process inspection. We do not wait until the end of the job to check for accuracy. Instead, our machinists use surface plates, indicators, height gages, and other precision instruments throughout the manufacturing process.

This layered approach to quality ensures that each gage is held to specification as it moves through the shop. Deviations are caught early, adjustments are made in real time, and rework is kept to an absolute minimum.

Final Inspection Anchors Our Quality Control Tooling Philosophy

Once a gage reaches final inspection, it is measured and documented using certified equipment including CMMs, optical comparators, and micrometers calibrated to NIST standards. Our inspection department follows detailed protocols to ensure that each gage meets or exceeds all customer specifications.

Every tool is delivered with full documentation, and we maintain inspection records for traceability. This is the final layer in our quality control tooling process, and it reflects our commitment to absolute accountability in every tool we deliver.

Custom Gaging Solutions Backed by Decades of Experience

Not every part can be measured with a catalog gage. That is why Veit Tool specializes in custom precision gage manufacturing for unique and complex parts. Whether it is a thread gage for an exotic form or a go/no-go fixture for a cast component, we design tools to solve measurement challenges others cannot.

Our customers rely on us not just as a vendor, but as a true manufacturing partner. We work collaboratively, often alongside quality engineers and manufacturing teams, to design gaging solutions that are fast, accurate, and easy to use on the production floor.

Calibration and Certification Reinforce Our Commitment to Quality

Every gage that leaves Veit Tool is backed by thorough inspection. In addition to internal checks, we offer gage certification services through ISO 17025 accredited labs. This ensures that our tools are traceable, verifiable, and ready for regulated environments.

Fast Turnarounds Without Compromising Precision

Many of our customers operate in fast-paced environments, and downtime is costly. That is why Veit Tool has streamlined our internal processes to deliver both speed and accuracy. From quoting to final delivery, we communicate clearly and deliver on our lead times.

We offer expedited options on most gage manufacturing jobs and maintain flexible scheduling to support urgent requests. Even with quick turnarounds, we never cut corners on quality. Every gage is held to the same standard, whether it ships in five days or five weeks.

Continuous Improvement Is Built Into Our Culture

Staying at the forefront of precision gage manufacturing means never standing still. At Veit Tool, we invest continually in new equipment, updated software, and employee training. We perform regular process audits and encourage feedback from both our team and our customers.

Our goal is to build gages that last and relationships that grow. By refining our quality control tooling methods, adopting new technologies, and listening to customer needs, we are always looking for ways to raise the bar.

Precision Gage Manufacturing That You Can Rely On

At Veit Tool, we understand that the gages we manufacture are the final word on part acceptance. They are the tools that confirm quality, ensure safety, and protect reputations. That is why we take precision gage manufacturing so seriously.

From the moment an order hits our system to the final inspection and delivery, every step of our process is designed to deliver accuracy, reliability, and confidence. Whether you need a single master plug gage or a suite of custom quality control tooling fixtures, you can count on Veit Tool to deliver.

Contact Veit Tool to learn more about our capabilities, or contact our team today to discuss your next project. When precision matters, Veit Tool delivers.

Stay Connected with Veit Tool!

Get company news and expert industry insights — spam-free and straight to your inbox. Sign up today!

Contact Us

(810) 658-4949

Send an Email

Headquarters

303 S. Dayton St.

Davison, MI 48423

Business Hours

Mon-Fri, 7:00am - 3:30pm

We're Hiring!

View Job Openings >