News & Insights

Comprehensive Gear Testing: Precision Roll Testing, Tooth-to-Tooth Analysis, Runout Inspection & More

When it comes to precision gears, there’s no room for error. Whether you’re manufacturing components for aerospace, automotive, or industrial applications, gear testing is a critical part of the process. Dimensional accuracy and functional performance both rely on the ability to detect flaws early and ensure compliance with tight tolerances. This post breaks down key methods and tools used in gear inspection—focusing on Roll Test Fixtures, tooth-to-tooth rollout, runout inspection, and composite inspection.

Why Gear Testing Matters

Every gear produced must meet stringent quality requirements to perform reliably under load. If gear geometry is even slightly off, it can cause premature wear, vibration, or failure in the final assembly. That’s why gear testing isn’t just a final step—it’s a core part of the manufacturing process.

At Veit Tool Inc, we engineer custom solutions to make gear testing faster, more repeatable, and more accurate, all while fitting seamlessly into your process. Whether you’re inspecting high-volume production runs or prototypes, your inspection process needs to be as precise as your machining.

Roll Test Fixtures: Fast, Reliable, Functional Inspection

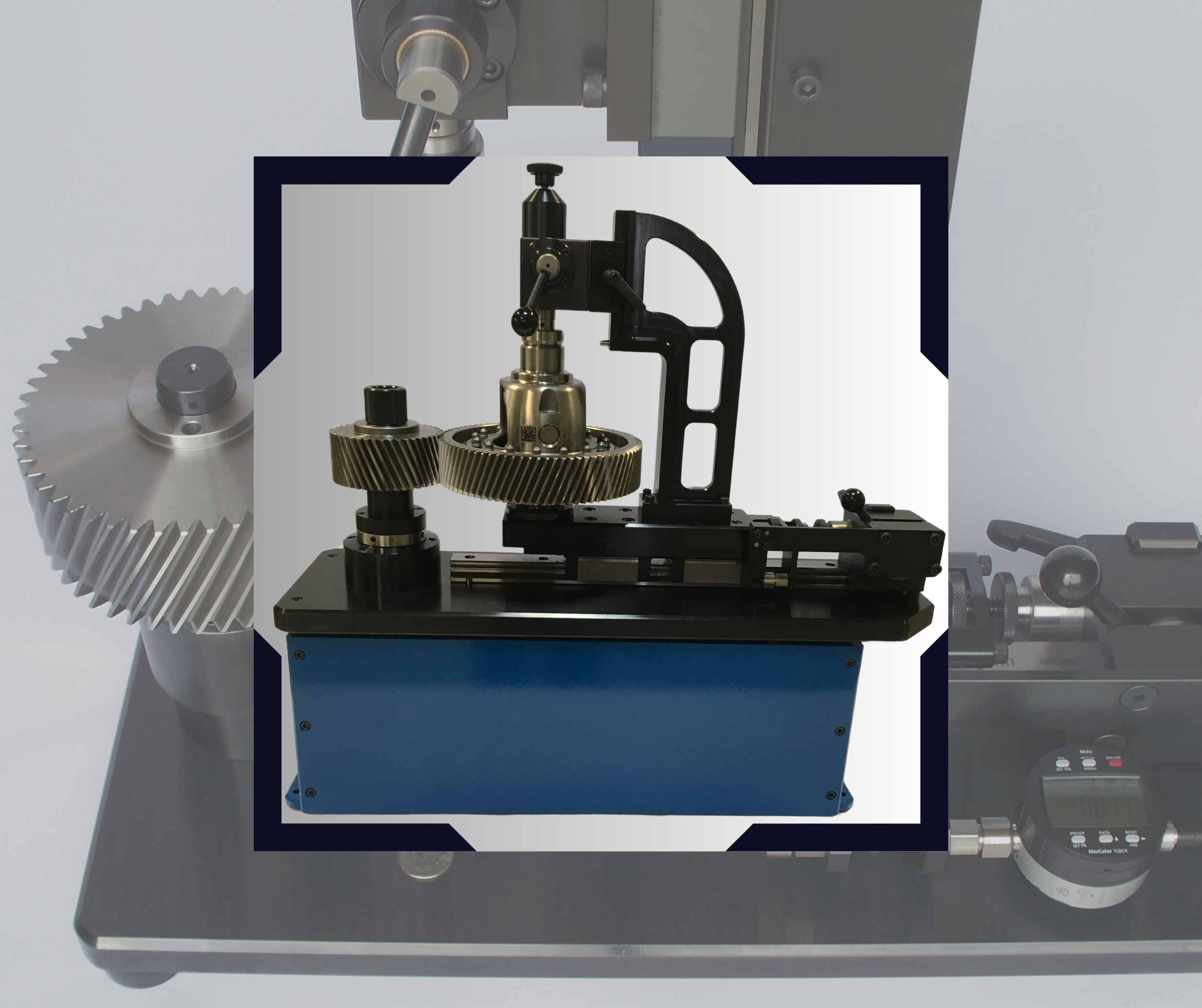

A roll test fixture provides a quick and reliable way to evaluate gear function without going through a full Coordinate Measuring Machine (CMM) inspection. Roll testing simulates how a gear will perform live by meshing it with a master gear.

There are two types of roll test fixtures: manual and motorized. Both can be used to check for errors in lead, pitch, and runout, but the motorized version offers advantages in terms of speed and repeatability.

Our manual and motorized Gear Roll Test Fixtures are built for performance and to provide a stable, consistent platform to assess backlash, tooth contact pattern, and overall gear performance—so you can catch issues before they become costly.

Tooth-to-Tooth Rollout: Finding the Details

Tooth-to-tooth rollout inspection measures variations from one gear tooth to the next. It’s an essential measurement when looking for localized defects that wouldn’t show up in a composite inspection alone. This method uses a roll test fixture with dial indicators or electronic probes to capture the minute differences in spacing or profile between individual teeth.

A high-quality gear should show minimal variation across the full rotation. Deviations can point to problems in tooling, misalignment in setup, or material inconsistencies.

At Veit, we design test fixtures that make tooth-to-tooth rollout easy to perform and interpret, even in high-volume production environments. Again, the goal is to catch irregularities early so you can make corrections before issues arise.

Runout Inspection: A Critical Check for Concentricity

Runout inspection measures how much the gear deviates from a perfect circle during rotation. It’s a key check for concentricity, and it helps identify problems like off-center bores or inconsistent tooth geometry.

There are two primary types:

- Radial runout, which measures variation in the radius from the centerline of the gear.

- Axial runout, which checks for flatness and wobbles across the gear face.

Both types of runout can cause vibration, noise, and accelerated wear in an assembly. Our Roll Test Fixtures are built to make runout inspection easy to integrate into your inspection workflow. Designed with rigid frames and precision guideways, our fixtures ensure you’re measuring the part—not flex or deflection in the system.

Composite Inspection: The Full Picture

Composite inspection uses roll testing to evaluate the combined effect of several potential gear errors—lead, pitch, runout, and profile. It’s less about measuring specific deviations and more about understanding how the gear will behave in real-world use.

This operational check is often used in production environments to sort good parts from bad quickly. It’s a go/no-go style test, but the information it provides is invaluable—especially when paired with more detailed checks like tooth-to-tooth rollout and runout inspection.

Veit Gear Roll Test Fixtures are designed to support this kind of composite inspection, giving you consistent results with every part. By simulating actual working conditions, you’re able to verify performance at speed and scale.

Integrating Gear Testing into Your Workflow

At Veit Tool Inc, we specialize in designing and building custom test fixtures that simplify complex inspection routines. Our team works with you to understand your part geometry, tolerances, and throughput needs. The result: inspection equipment that doesn’t just meet the spec—it supports better productivity.

Whether you need a standalone Gear Roll Test Fixture or a complete system that includes indicators, drives, and data collection, we can build a solution that fits your process.

Gear Testing: Not Just a Final Step

Gear inspection is more than a box to check at the end of production. It’s a process that guides machining, setup, tooling, and even part design decisions. The data you gather—whether from a runout inspection, composite test, or tooth-to-tooth rollout—can drive improvements and help you maintain tighter control over every part that leaves your shop.

From short runs to high-volume production, our gear testing fixtures are built for real-world use. They’re rugged, accurate, and easy to operate—inspection should never be the bottleneck.

Looking to Improve Your Gear Inspection Process? If you’re ready to take gear testing to the next level, we’re here to help. Contact us to learn more about custom Roll Test Fixtures and integrated inspection solutions designed for your exact part and process.

Stay Connected with Veit Tool!

Get company news and expert industry insights — spam-free and straight to your inbox. Sign up today!

Contact Us

(810) 658-4949

Send an Email

Headquarters

303 S. Dayton St.

Davison, MI 48423

Business Hours

Mon-Fri, 7:00am - 3:30pm

We're Hiring!

View Job Openings >