News & Insights

Gear Burnishing Systems Enhance Precision and Productivity

When it comes to finishing gears with speed, consistency, and accuracy, gear burnishing systems are unmatched. This non-cutting process is critical for refining the surface of heat-treated gears, eliminating minor imperfections while maintaining exact tooth geometry. For manufacturers who rely on high output and exceptional quality, gear burnishing systems are a smart investment that delivers both performance and value.

At Veit Tool, we’ve been building and refining our burnishing systems since 1988. Our systems are engineered for real-world demands and deliver consistent, high-volume results.

Gear Burnishing Systems Improve Surface Quality Without Material Removal

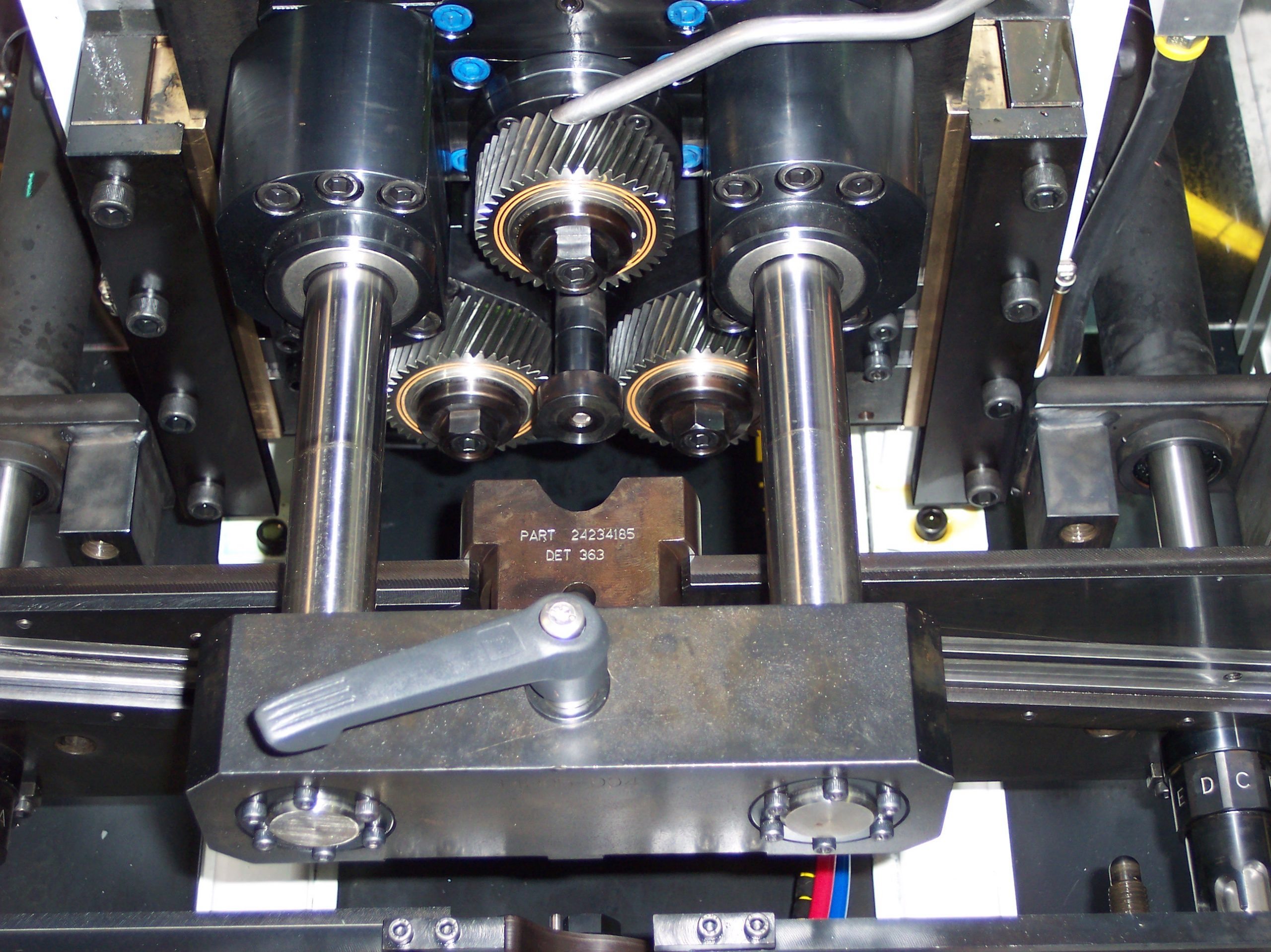

Gear burnishing is a unique process that uses pressure and oscillation, not cutting, to refine the surface finish of gears. During the burnishing cycle, hardened burnish rolls rotate against a heat-treated gear under load. This action compresses surface asperities and removes heat-treat scale, leaving a cleaner, smoother tooth flank.

Unlike grinding or honing, gear burnishing systems do not remove material. That makes them ideal for finishing gears after heat treatment without altering critical geometry. This also reduces the need for secondary inspections or rework, streamlining production and improving throughput.

Gear Burnishing Systems Designed by Veit Tool Offer Options for Every Operation

Veit Tool offers a full lineup of gear burnishing systems designed to meet a wide range of automation and production needs:

Model 1000 – A semi-automatic system featuring manual load and unload. Ideal for low to moderate production runs or operations with frequent part changes.

Model 2000 – This system includes automatic roll-in and roll-out handling, offering a balance of speed and operator efficiency.

Model 3000 – Our fully automated, CNC-servo-driven burnisher built for high-volume, lights-out production. This system provides full automation and integration readiness for modern manufacturing environments.

Each system is built for reliability, simplicity, and long-term use, with intuitive controls and maintenance-friendly design.

Gear Burnishing Systems Deliver High Output and Consistent Quality

Manufacturers choose Veit Tool’s gear burnishing systems for one simple reason: results. Our systems are capable of processing up to 600 parts per hour, depending on gear size and configuration. That means higher productivity without sacrificing precision.

Benefits of Veit burnishing systems include:

- Dramatic reduction in nicks, burrs, and heat-treat scale

- Consistent surface finish across all flanks

- Improved gear longevity and performance

- Reduction in post-processing and manual inspection time

- Integration with lean manufacturing principles

By finishing gears more quickly and cleanly, these systems reduce labor costs and improve first-pass yield.

Gear Burnishing Systems Include Precision Controls and Safety Features

Every Veit Tool gear burnishing system is engineered with advanced features that make operation efficient, safe, and repeatable:

- Cam-activated oscillation between burnish and work gears

- PLC control and HMI touchscreen for simple setup and real-time diagnostics

- Auto-lube and mist-collection systems for cleaner, longer-lasting operation

- Tool-less part changeover for fast transitions between different gear types

- Full enclosure with safety interlocks and stack lights to ensure operator protection

These features help reduce downtime, promote safety, and simplify operator training, all while ensuring a high-quality finish every time.

Gear Burnishing Systems Support Critical Industries

Gear burnishing systems are essential for any industry where gear performance matters. From smooth transmission in automotive systems to precise motion control in aerospace and defense applications, a properly finished gear makes all the difference.

Veit Tool’s systems are used across industries such as:

- Automotive – Transmission gears, powertrain components, steering systems

- Aerospace – Actuation mechanisms, accessory drive systems

- Defense – Weapon systems, ground support gearing

- Industrial Machinery – Pumps, gearboxes, conveyor drives

Our gear burnishing systems are especially popular among Tier 1 and Tier 2 suppliers who need to meet strict tolerances while keeping production rates high.

Gear Burnishing Systems Integrate Seamlessly Into Production Lines

Our burnishing systems are designed to complement existing gear manufacturing workflows. Whether you’re running a manual setup or a fully automated line, Veit Tool provides integration-ready solutions to fit your needs.

Considerations for integration include:

- Automation level and part handling strategy

- Production footprint and workspace constraints

- Tooling and fixture requirements for gear variants

- Coordination with post-process inspection tools, such as roll testers or composite gages

Veit Tool also provides support during installation and training, so your team can start seeing results quickly.

Gear Burnishing Systems Provide a Measurable Return on Investment

A well-built burnishing system pays for itself through increased throughput, fewer quality issues, and lower labor costs. Customers often report:

- Reduced scrap and rework

- Faster cycle times

- Greater consistency from operator to operator

- Improved gear performance in field applications

For many operations, the decision to invest in gear burnishing systems comes down to long-term efficiency. With a lifecycle of decades and a reputation for reliability, Veit systems deliver real value over time.

Gear Burnishing Systems from Veit Tool Are Built with Experience

Since 1988, Veit Tool has specialized in high-precision tooling and equipment for the gear manufacturing industry. Our gear burnishing systems are built on decades of insight, customer feedback, and continuous improvement.

We design, build, and support every system right here in the USA, and our team is always available to help with applications engineering, system customization, and technical support.

Whether you’re adding your first burnishing machine or upgrading an entire line, Veit Tool is your partner in precision.

Learn More About Veit Tool Gear Burnishing Systems

If you’re ready to elevate your gear finishing process, download the gear burnishing systems spec sheet or request a quote directly from our website. You can also contact our team for a consultation or schedule a live demonstration.

Let us show you how a gear burnishing system from Veit Tool can transform your production floor with precision, speed, and dependability.

Stay Connected with Veit Tool!

Get company news and expert industry insights — spam-free and straight to your inbox. Sign up today!

Contact Us

(810) 658-4949

Send an Email

Headquarters

303 S. Dayton St.

Davison, MI 48423

Business Hours

Mon-Fri, 7:00am - 3:30pm

We're Hiring!

View Job Openings >