News & Insights

Veit Roll Testers: Precision in Gear Inspection

Understanding the Roll Tester: From Manual to Fully Automated

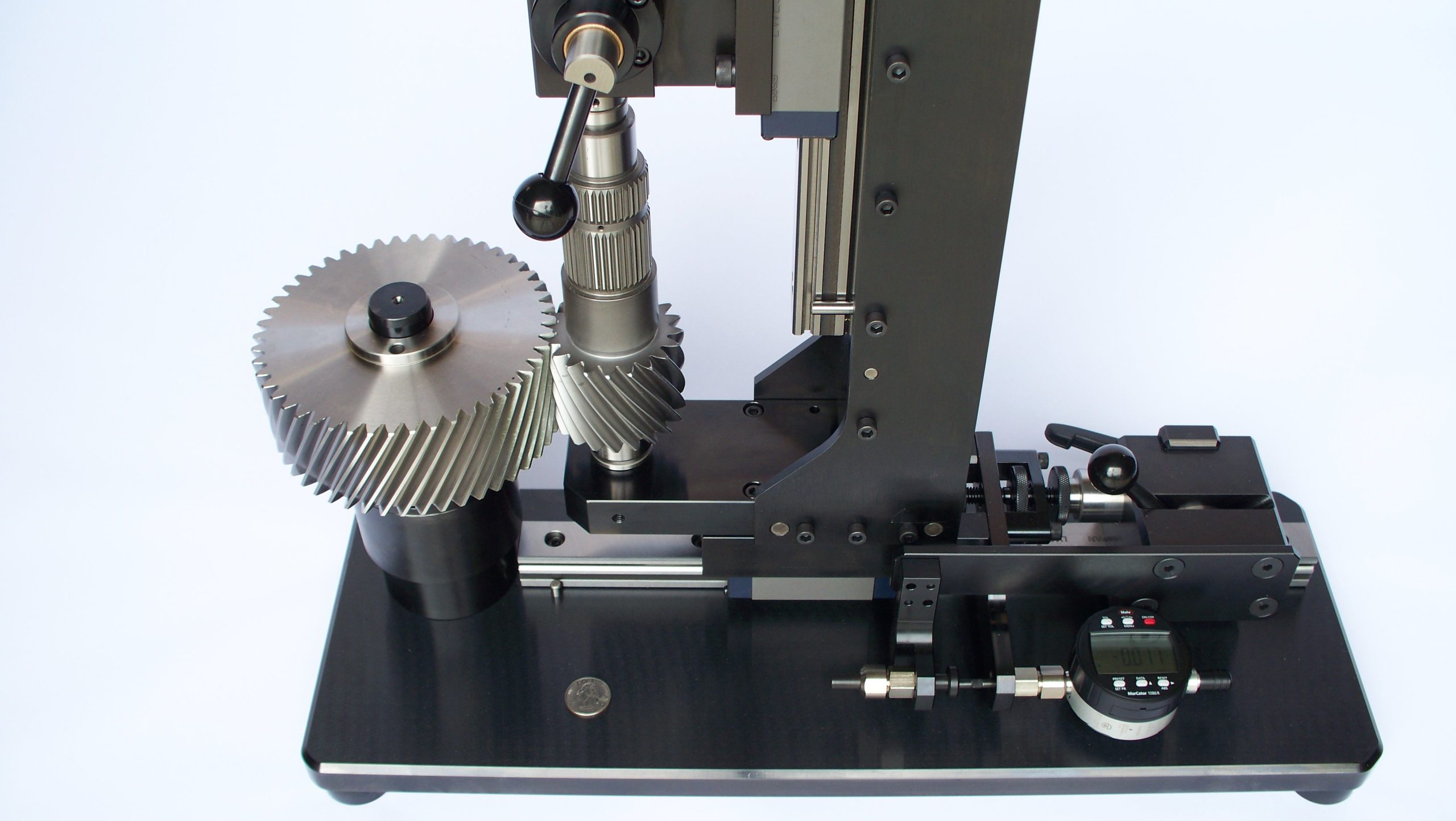

When you first encounter the term roll tester, think functional inspection, not just geometry. Roll testing simulates live gear meshing, revealing pitch deviations, runout, or subtle tooth anomalies without the time sink of a full CMM scan. As explained in the video overview, our offerings span from basic roll testers to fully automated solutions that can be seamlessly integrated into production workflows.

Manual Roll Testers: Simplicity Meets Precision

A manual roll tester offers a compact, cost-effective gateway into functional gear inspection. With sturdy construction and fine-tuned indicators—manual or electronic—these units are tough enough for the shop floor, accurate enough for trusted analysis. They’re ideal for smaller parts, prototypes, or lower-volume runs that still demand meticulous validation.

Motorized & Automated Roll Testers: Precision at Scale

Need speed without sacrificing reliability? Our motorized and fully automated roll testers step in with high-speed automation, programmable engagement pressures, and seamless data capture. These systems pump throughput while keeping repeatability tight, perfect for high-volume gear production. Imagine consistent test cycles with minimal operator input, all feeding data into your process control system.

Why Choose a Roll Tester for Gear Inspection?

Here’s why our roll testers are engineered to be indispensable assets in your quality workflow:

- Functional Relevance

- Measurements reflect how gears actually perform under load and in mesh, not just static geometry.

- Efficient Workflow Integration

- Manual units are compact and easy to use. Automated versions plug right into production lines, scaling with your throughput.

- Broad Applicability

- Suitable for different gear types, pitches, and sizes—fine to coarse, plastic to hardened.

- Repeatability You Can Trust

- Each roll tester is built with precision bearings, tight tolerances, and optional tensioned slides, ensuring consistent results across thousands of cycles.

- Data‑Driven Inspection

- Electronic indicators and digital probes facilitate streamlined logging and analysis for validating runout or profiling tooth-to-tooth consistency.

Key Inspection Modes: What You Can Do with a Roll Tester

Roll Testing (Composite Inspection)

Roll testing shines in what we call “composite inspection”, giving you a go/no-go snapshot of combined lead, pitch, and runout behaviors. Rather than isolating individual metrics, this method captures the gear’s overall operational integrity in real-world performance.

Tooth-to-tooth Rollout

Subtle variations between neighboring teeth? Tooth‑to‑tooth rollout flags them. Using a roll tester equipped with precision indicators, you can detect localized defects, from uneven spacing to minor tooling issues, before they cascade into functional failure.

Runout Measurement

Runout inspection—both axial and radial—is crucial to gear performance. Axial runout reveals surface wind-up; radial runout uncovers eccentricity. Properly fixtured, our roll tester isolates part deviation from machine deflection, giving you a crystal-clear read on the gear’s concentricity.

Tailor-Made Testing: Configuring Your Roll Tester Setup

Whether manual or motorized, every roll tester is customizable. At Veit Tool, we offer options like:

- Pneumatic actuation for controlled mesh pressures

- Between‑center attachments for shaft or complex parts

- Adjustable engagement force to accommodate fine-pitch or delicate materials

- Sensitive slides with force gauges for force‑critical components

Plus, integration-ready data systems including wireless electronic indicators, digital probe interfaces, and Windows-based gear inspection software ensure that your results are captured seamlessly and smartly.

Real-World Impact: Roll Testers in Action

Imagine a mid-tier automotive supplier pushing gear quality through high-volume production. A manual roll tester offers quick checks during setup or prototype stages. As volume ramps up, they introduce a motorized roll tester for automatic, rapid validation, which maintains quality without slowing throughput.

Or picture a tooling shop working with both plastic planetary gears and hardened steel pinions. A configurable roll tester lets them dial in force for delicate gears while pushing harder for rigid materials, always delivering relevant, reliable data.

Integrating Roll Testers into Your Workflow: Best Practices

- Standardize Test Inputs

Use the same master gear, consistent torque, and preset engagement pressure to improve repeatability. - Automate Where Possible

Motorized systems save time and cut operator error, especially in high-volume setups. - Align Data Capture

Detect trends (like gearwear over time) via consistent logging from electronic indicators or probe systems. - Respond Actively

Every failed part is feedback. Early detection through roll testing can drive upstream process improvements in machining or tooling.

Why Veit Tool’s Roll Testers Stand Out

We’ve built a reputation on thoughtful engineering, machining excellence, and applied precision. Our roll testers reflect that heritage; engineered for use, designed to last. Whether it’s a compact manual fixture or a line-ready automated setup, our commitment is the same: real-world accuracy you can depend on.

From custom configurations tailored to your specifications, to rugged construction that withstands daily shop abuse, if it needs testing, we’ve got the gear for it.

Bringing It All Together

When motorized systems meet bespoke design, and practical usability meets data-driven precision, that’s the power of the roll tester. At Veit Tool, we help you embrace inspection that’s fast, functional, and future-ready.

Ready to upgrade your gear inspection? Whether you want a fundamental roll tester for quick functional checks or a fully automated, data-driven solution for production-scale testing, we’re here to tailor it to your exact needs. Get in touch with Veit Tool, and let’s test smarter.

Stay Connected with Veit Tool!

Get company news and expert industry insights — spam-free and straight to your inbox. Sign up today!

Contact Us

(810) 658-4949

Send an Email

Headquarters

303 S. Dayton St.

Davison, MI 48423

Business Hours

Mon-Fri, 7:00am - 3:30pm

We're Hiring!

View Job Openings >