News & Insights

Unlocking Precision with 5-Axis Machining at Veit Tool

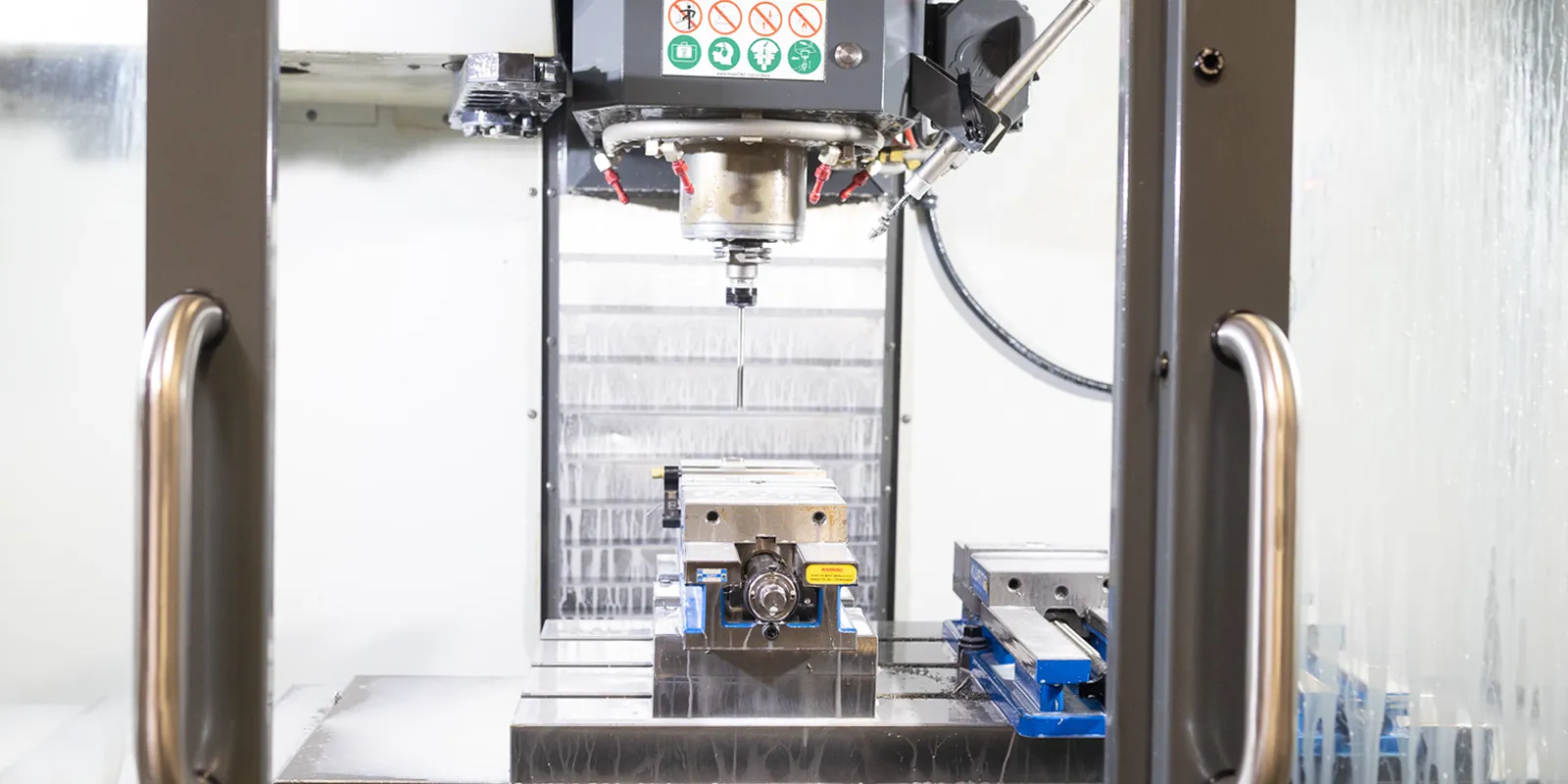

Precision and efficiency are the cornerstones of success in manufacturing. One technology that has radically transformed the industry is 5-Axis CNC machining. With its unparalleled ability to deliver intricate, high-quality components, 5-Axis machining is now a game-changer for industries ranging from aerospace to medical devices. At Veit Tool, we use MasterCam programming software, along with 5-axis machining, to offer our clients exceptional precision and complex part production for both 2D and 3D machining.

What is 5-Axis CNC Machining?

At its core, 5-Axis CNC machining refers to the ability of a machine to move a cutting tool or the workpiece along five different axes simultaneously. Unlike traditional 3-axis machining, where the cutting tool moves along the X, Y, and Z axes only, 5-Axis machines add two additional rotational axes. These two additional rotational axes provide the flexibility to approach the part from multiple angles.

As the cutting tool can reach almost every side of the workpiece, it dramatically reduces the need for repositioning, which not only saves time but also boosts precision by minimizing human error and part misalignment. This added complexity allows manufacturers to achieve superior surface finishes and more intricate designs in less time.

How Does 5-Axis CNC Machining Work?

To break it down simply, a 5-Axis machine works by controlling the movement of both the tool and the workpiece. The five axes of movement are:

Standard Linear Movements

- X – horizontal along the length (forward/backward)

- Y – horizontal along the width (left/right)

- Z – vertical perpendicular (up/down)

Rotational Movements

- A – rotational around the X-axis

- B – rotational around the Y-axis

This combination of linear and rotational movements means that parts can be machined from virtually any angle, allowing for the production of complex geometries and intricate features that would be impossible or difficult to achieve with traditional 3-axis systems.

Veit Tool specializes in leveraging this sophisticated technology to create high-precision parts, minimizing setup times and cutting down on production costs. The versatility of 5-Axis machining makes it an essential tool for industries that require tight tolerances and superior finishes, including aerospace, medical, automotive, and defense sectors.

Advantages of 5-Axis Machining

Higher Precision and Accuracy

The ability to machine complex parts without repositioning reduces the risk of inaccuracies. When compared to 3-Axis machining, the precision of 5-Axis systems allows for tighter tolerances, ensuring that the final product meets the most stringent quality standards.

Increased Efficiency

With the simultaneous multi-axis movement, 5-Axis machines can perform more operations in a single setup. This eliminates the need for multiple tool changes or repositioning, ultimately speeding up the production process and reducing cycle times.

Ability to Handle Complex Geometries

5-Axis machining opens up possibilities for producing intricate and complex shapes that would be difficult, if not impossible, to achieve using traditional methods. This capability allows for greater design freedom.

Improved Surface Finish

The added precision and flexibility in movement not only enhance the accuracy of parts but also result in superior surface finishes. Parts produced with 5-Axis machining often require less post-processing work, leading to cost savings in finishing.

Reduced Tool Wear

Since the cutting tool can be oriented in various angles during the machining process, tool wear is spread out more evenly. This reduces the overall wear and tear on the tooling and extends its lifespan, leading to fewer replacements and reduced operational costs.

Why Choose Veit Tool for your 5-Axis Machining?

At Veit Tool, we take pride in our state-of-the-art 5-Axis CNC machining capabilities. Our team is highly experienced in working with these advanced systems, and we consistently deliver parts that meet the highest standards of precision, quality, and efficiency. So if you’re in need of low-volume, high-precision prototypes, we have the expertise and equipment to meet your needs.

At Veit Tool, we take pride in our state-of-the-art 5-Axis CNC machining capabilities. Our team is highly experienced in working with these advanced systems, and we consistently deliver parts that meet the highest standards of precision, quality, and efficiency. So if you’re in need of low-volume, high-precision prototypes, we have the expertise and equipment to meet your needs.

Our dedication to cutting-edge technology allows us to take on complex projects that require precision at every step. By pairing our MasterCam software with our Haas VF2SS with TRT210, we can ensure that your designs are brought to life with the utmost accuracy and at a competitive cost.

If you’re looking for a partner who can turn your complex designs into reality, Veit Tool is the perfect fit. Let us help you unlock the full potential of your manufacturing process with our advanced 5-Axis machining and milling capabilities.

For more information, Contact us today to discuss your next project!

Stay Connected with Veit Tool!

Get company news and expert industry insights — spam-free and straight to your inbox. Sign up today!

Contact Us

(810) 658-4949

Send an Email

Headquarters

303 S. Dayton St.

Davison, MI 48423

Business Hours

Mon-Fri, 7:00am - 3:30pm

We're Hiring!

View Job Openings >